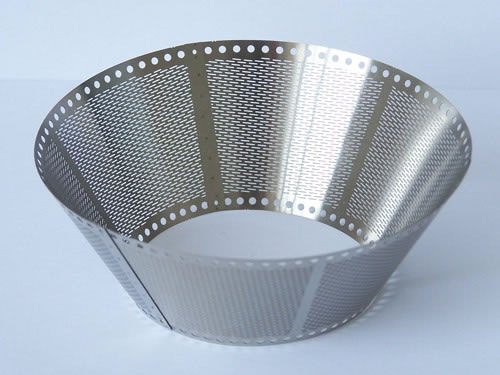

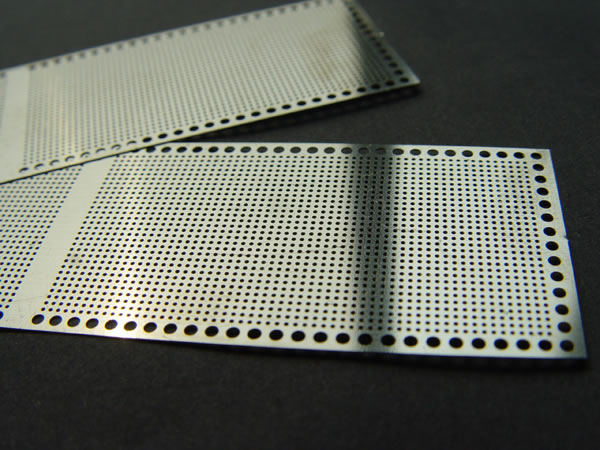

MICRO HOLE ETCHED METAL |

Material: Stainless steel, Copper plate.

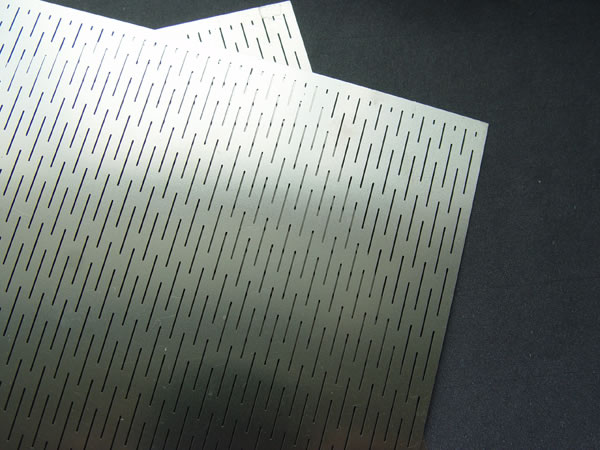

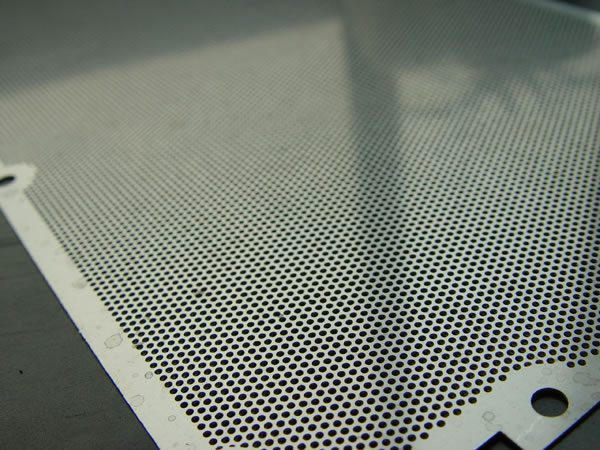

Metal Etching is also known as photo etching or checmical etching which is a high precision, tightly controlled corrosion process, used to produce complex metal parts with very fine detail, sect metal net ,metal crafts etc.

Metal etching process offers more effective alternative to stamping, punching, laser and waterjet cutting, when machining precision components from thin gauge materials, such as stainless steels, copper plate.

Hi-Meta Metal offers all kinds of precise etching metal sheet, precise filter, shaped wire mesh, nameplate, juice machine filter, metal mobile keyboard, razor sheet, precise electronics parts, anit-in

Thickness: 0.05mm-1.5mm

Max Size:500x600mm

Burr and Stress Free

As a cold chemical process that removes unwanted material, the photo etching process does not induce stress or deformation. Parts which are pressed or stamped are often subjected to substantial mechanical forces and stresses. Photo etched components are burr free, while temper and magnetic properties remain unchanged.

Fast and Economical

Using digital tooling, Metal Spec can produce samples sooner than puncing.helping Tooling costs are minimal, allowing customers to modify and optimise their designs without significant cost penalty. Photo etching is ideal for those wishing to adopt a low risk strategy to product development.

High Complexity and Accuracy

Because of the nature of the photo etching process, complex designs cost no more to produce than simple ones.Metal etching have a very high accuracy than the punching metal. Hi-Meta Metal will offer you a full solution for a micron hole metal plate.

sales1

sales1